INPROTEC IRT will be present at the international die casting trade fair ‘EUROGUSS 2026’ at the ChemTrend stand.

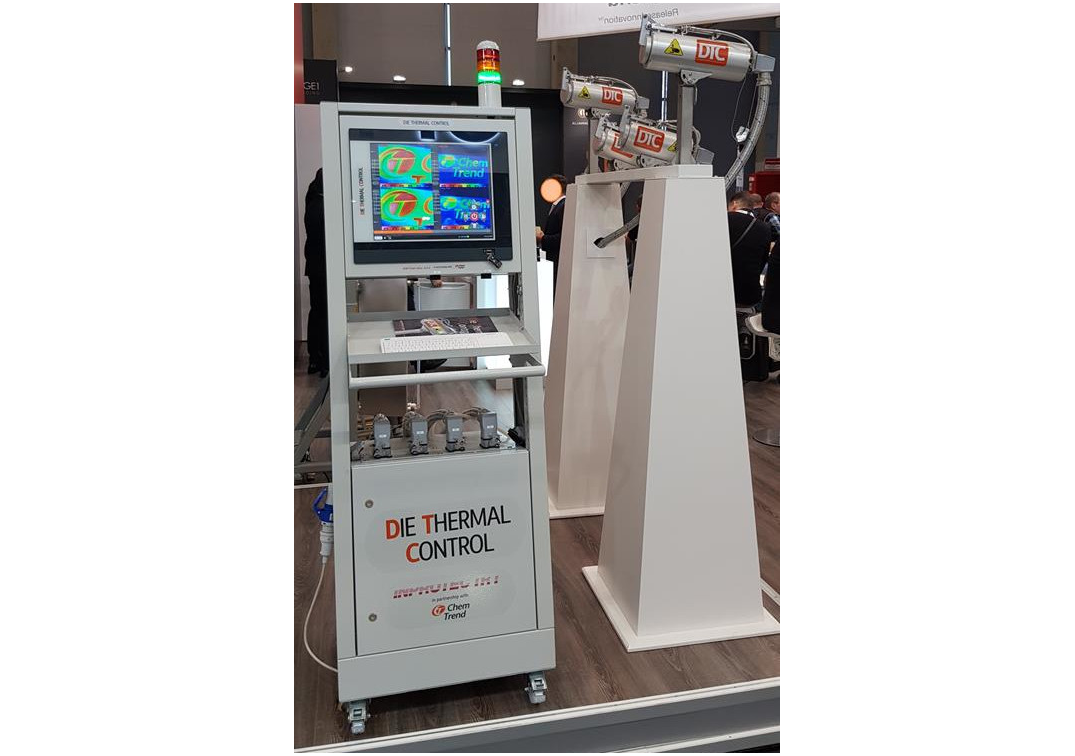

For the occasion, we will be presenting a new and innovative DTC (Die Thermal Control) thermographic system.

Come and discover and learn about the new product we will be presenting.

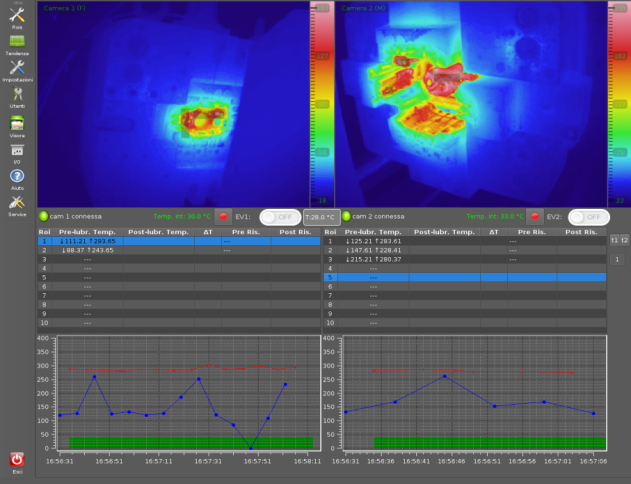

- 模块化设计DTC单元可连接多达4个红外线辐射测量探头,进而实现抓取并测量具有复杂表面以及型腔结构的模具表面温度。

- 复杂结构件例如发动机缸体,变速箱壳体最佳温度监测方案(如果仅使用2个探头不能直观覆盖模具表面结构以及内部型腔结构)

DTC - DIE THERMAL CONTROL

Brand new Die Thermal Control unit helps you stay cool in the heat of die casting.

Watch a video of the DTC in the die casting industry

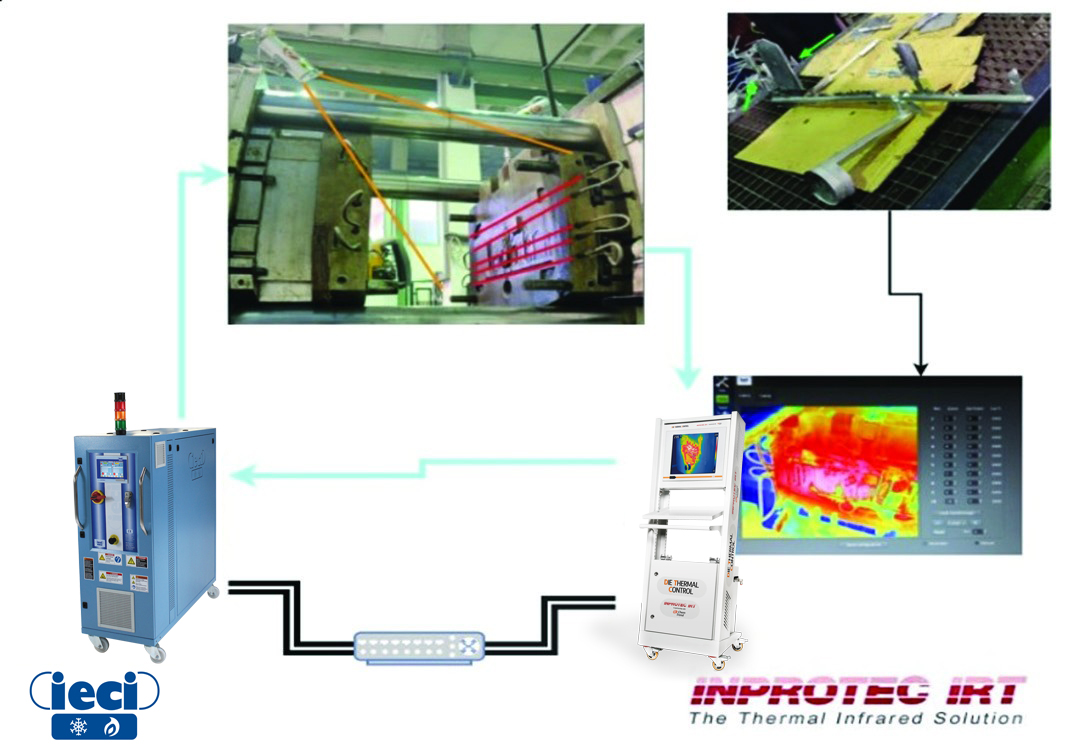

In the die-casting industry, thermography is a highly used technology that helps to understand how to obtain the best thermal balance of the mould by mainly acting on thermoregulation and proper application of the release agent.

With its 20 years of experience in supplying portable thermal imaging cameras in foundries, INPROTEC IRT has transpose the request from customers by delivering the first Thermography System for die-casting process control for Factory 4.0.

“Smart production” means new production technologies that create connection between all the elements present in the production. That is, they create the ideal working conditions to maximize potential and coordinate operators, machines, tools and management. The “Die Thermal Control” DTC system developed in collaboration with Chem-Trend is an "open" system that fully meets the requirements of "Factory 4.0" with:

-

No. 40 I/O for interfacing and integration with other devices

-

No. 2 Analog inputs for future applications

-

Interfaces with peripherals as Spray Lubrication heads, Thermoregulation units, HPDC machines, etc.

-

Customization required by the customer

After sales support and technical assistance

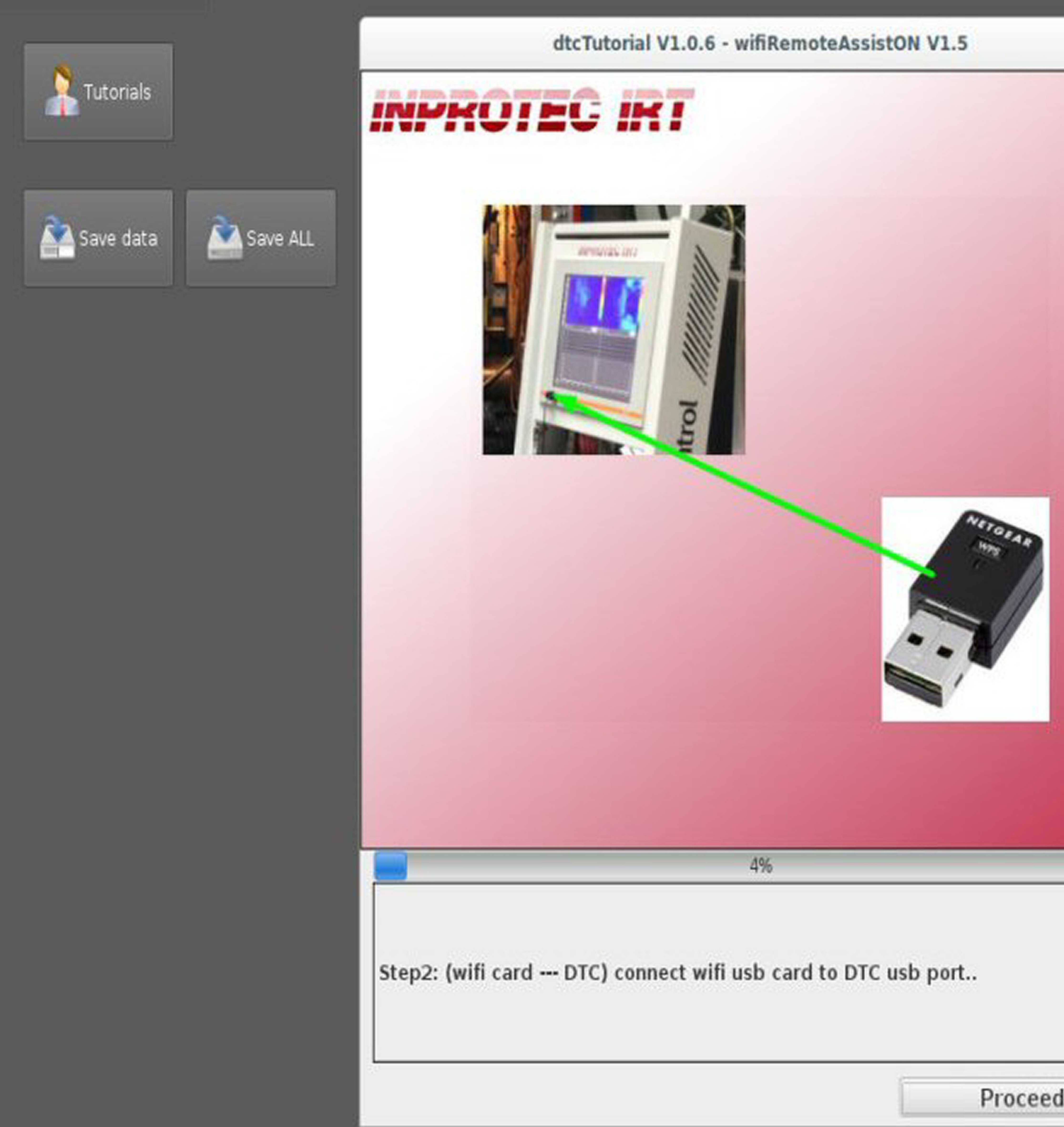

The DTC system comes in standard configuration with remote support, updates, using iOS (iPhone), Android, with Wi-Fi keys, Ethernet Connection.

DTC System

Main page on Panel PC of the management software.

Español

Español  Română

Română  Italiano

Italiano  Deutsch

Deutsch  Français

Français  Chinese

Chinese  English

English